Effective thermal management is the key to unlocking the full potential and lifespan of modern LED lighting. Heat is the primary enemy of LED performance, and without an efficient way to dissipate it, bulbs can dim prematurely and fail. What is the best aluminum for a heat sink? While many materials can conduct heat, 1060 aluminum has emerged as the superior choice for LED heat sink applications. This deep dive will explore the scientific and practical reasons why this specific alloy is the ultimate material for your lighting projects.

What is 1060 Aluminum? A Quick Overview

Before we analyze its benefits, let's quickly understand the material itself. What is 1060 aluminum? It is a commercially pure, non-heat-treatable aluminum alloy known for its excellent workability and high purity.

Composition and Purity: The "1000 Series" Advantage

Belonging to the 1000 series aluminum family, 1060 aluminum contains a minimum of 99.6% aluminum. This high purity is the primary reason for its exceptional thermal and electrical properties. The low level of alloying elements results in a soft, highly ductile material.

Key Mechanical and Physical Properties

Beyond its purity, 1060 aluminum is valued for its low density, excellent corrosion resistance in normal environments, and superb formability. These 1060 aluminum properties make it an ideal candidate for manufacturing processes like stamping and forming.

The Number One Reason: Superior Aluminum Heat Conduction

Why is thermal conductivity important? For an LED heat sink, the single most critical property is its ability to move heat away from the sensitive LED chip. In this area, 1060 aluminum is a clear champion.

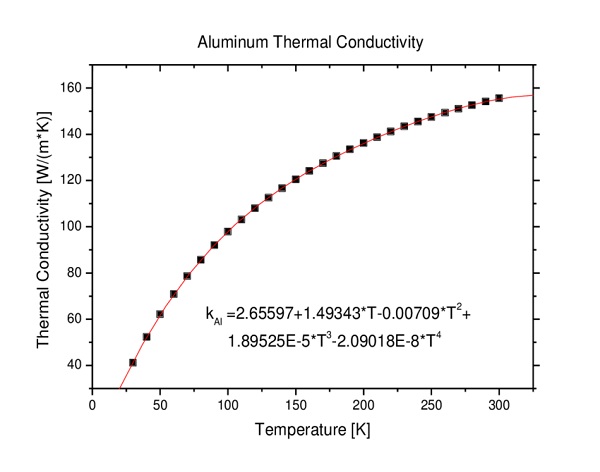

Understanding Thermal Conductivity (W/mK)

Thermal conductivity is a measure of a material's ability to transfer heat, typically expressed in Watts per meter-Kelvin (W/mK). A higher number means the material can move heat more quickly and efficiently. Effective thermal management solutions depend on materials with high thermal conductivity.

How 1060 Aluminum Outperforms Other Alloys

With a thermal conductivity of around 230 W/mK, 1060 aluminum is one of the best performers among common aluminum alloys. Its high purity minimizes interruptions in the material's crystal structure, allowing thermal energy to flow freely. This makes it significantly more effective at dissipating heat than many other structural aluminum alloys. For custom thermal solutions, explore Pengce Metal's capabilities.

Lightweight by Nature: Optimizing Your Thermal Management Solutions

In modern product design, every gram matters. The inherent lightweight nature of 1060 aluminum provides significant advantages beyond just its thermal performance, impacting everything from product design to logistics.

The Impact of Density on Product Design

Aluminum is roughly one-third the weight of steel. This low density gives designers incredible freedom. It allows for the creation of larger, more effective heat sink surface areas without adding significant weight to the final product. This is crucial for fixtures mounted on ceilings or in weight-sensitive applications.

Reducing Structural Load and Shipping Costs

A lighter product means less structural support is needed for installation, simplifying the overall design. Furthermore, reduced weight directly translates to lower shipping and handling costs, a significant factor in cost-effective mass production and global distribution.

Cost-Effectiveness: Achieving High Performance on a Budget

High performance does not have to come with a high price tag. 1060 aluminum offers a fantastic balance of top-tier thermal performance and economic viability, making it a smart choice for competitive markets.

Raw Material Affordability

As a commercially pure and widely available alloy, 1060 aluminum is one of the most affordable grades. This allows manufacturers to source high-quality material without inflating the project budget, a key consideration for any custom aluminum heat sink project.

Excellent Formability for Lower Stamping Costs

The high ductility and softness of 1060 aluminum give it excellent formability. It can be easily stamped, bent, and formed into complex shapes with less force and lower tool wear compared to harder alloys. This ease of manufacturing reduces stamping costs and speeds up production cycles.

Pengce Metal: Your Expert Manufacturer for Custom LED Heat Sinks

Understanding the material is only half the battle. You need a manufacturing partner who has the experience and equipment to turn that material into a high-performance part. As a leading custom aluminum heat sink manufacturer, Pengce Metal is that partner.

Our Experience in Stamping 1060 Aluminum

We have extensive hands-on experience in manufacturing parts from 1060 aluminum. We understand its unique properties and have optimized our stamping processes to maximize efficiency and maintain tight tolerances, ensuring your custom aluminum heat sink performs flawlessly.

From Prototype to High-Volume Production

Whether you need a small batch of prototypes to validate your design or a high-volume run for mass production, we have the capacity to deliver. Our streamlined workflow ensures a smooth transition from initial concept to final product. Start your heat sink project with us today.

The Clear Winner for Your Next LED Lighting Project

When you weigh the evidence, the conclusion is clear. With its unbeatable combination of superior thermal conductivity, lightweight properties, and cost-effectiveness, 1060 aluminum stands out as the ideal material for LED heat sink applications. It delivers the high performance required for modern lighting while keeping budgets in check. What are the biggest thermal challenges you're facing in your lighting designs? Let's discuss in the comments!

Answering Your Questions on 1060 Aluminum Heat Sinks

Is 1060 aluminum better than 6061 or 6063 for heat sinks?Yes, for pure thermal performance, 1060 aluminum is significantly better. 6061 and 6063 are structural alloys with lower thermal conductivity (around 167-200 W/mK) because their alloying elements impede heat flow. They are stronger, but for a dedicated heat sink where heat dissipation is the primary goal, 1060 is the superior choice.

Does 1060 aluminum require any special surface treatment for corrosion resistance?In most indoor and standard environments, the natural oxide layer of 1060 aluminum provides sufficient corrosion resistance. For harsher environments or for aesthetic purposes, an additional treatment like anodizing is recommended.

Can 1060 aluminum be anodized?Absolutely. 1060 aluminum is excellent for anodizing. An anodized aluminum surface not only enhances corrosion and wear resistance but can also slightly improve thermal emissivity, further boosting the heat sink's performance. It can also be dyed in various colors for branding or aesthetic requirements.

How do I get a quote for a custom 1060 aluminum heat sink from Pengce Metal?Getting a quote is simple. Prepare your 2D or 3D design files, specify the material as 1060 aluminum, and let us know your estimated quantity and any finishing requirements. Our team will provide you with a competitive and detailed quote promptly. To begin, contact our experts at Pengce Metal.