In a busy warehouse or on a factory floor, industrial hardware is subjected to relentless punishment. For components like angle brackets on industrial carts, failure is not an option. This case study explores how Pengce Metal went beyond simple manufacturing to provide an engineering-led solution for a client needing exceptionally durable metal fittings. We will detail our process for a custom angle bracket design, demonstrating how modern engineering tools can create a truly heavy-duty bracket.

The Challenge: Extreme Loads and Dynamic Stress

Our client, a manufacturer of material handling equipment, needed a 90-degree angle bracket for their new line of industrial carts. The challenge was to design a component that could reliably handle the demanding environment.

Supporting High Payloads without Deformation

The primary requirement was that the bracket must support significant static weight without any permanent deformation. The carts were designed to carry heavy loads, and the brackets were a critical structural element.

Withstanding Shock and Vibration from Movement

Beyond static loads, the hardware had to endure constant dynamic stress. This included shocks from rolling over uneven surfaces and persistent vibration during movement, both of which can lead to material fatigue and failure over time.

Maintaining Cost-Effectiveness for High-Volume Production

While performance was key, the bracket also needed to be manufactured cost-effectively in high volumes to ensure the final product remained competitive in the market.

Our Engineering-Led Solution

We approached this not as a simple stamping job, but as an engineering problem. Our solution was a three-step, data-driven process focused on design optimization.

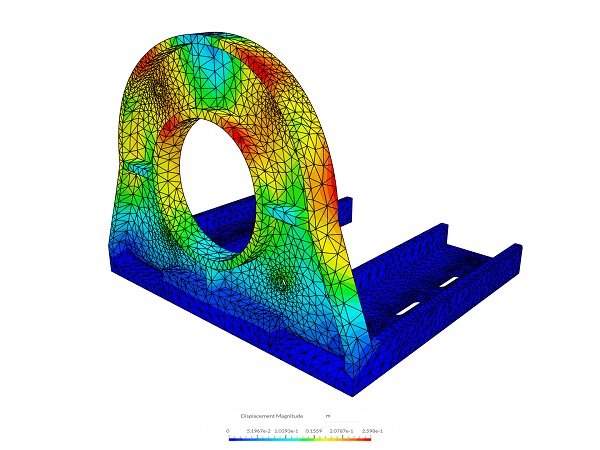

Step 1: Finite Element Analysis (FEA) for Design Optimization

Before cutting any steel, we utilized Finite Element Analysis (FEA) software. We created a digital model of the initial bracket design and applied simulated loads to identify stress concentration points. This analysis allowed us to intelligently add material and optimize the geometry where it was needed most, enhancing strength without adding unnecessary weight.

Step 2: Material Selection - Leveraging Hot-Rolled Steel's Strength

Based on the strength requirements and cost targets, we selected hot-rolled steel. Its excellent toughness and high strength properties made it the ideal material to withstand the demanding loads. You can learn more in our guide to hot-rolled steel.

Step 3: Stamping Process Design for Maximum Durability

We designed the stamping process and tooling to preserve the material's integrity. The bend radii and forming operations were carefully planned to minimize internal stress in the material, further contributing to the bracket's overall durability.

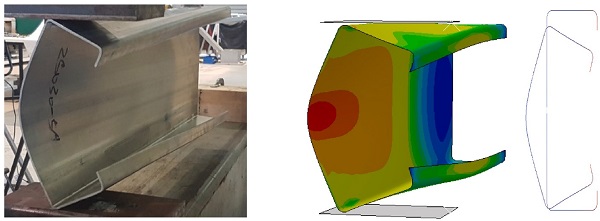

From Digital Simulation to Physical Reality

A great design must be executed flawlessly. We translated our optimized digital model into a robust physical product through precision manufacturing and rigorous validation.

Precision Tooling for a Robust Angle Bracket Design

We built a high-quality stamping die based on the optimized angle bracket design. The precision of this tool ensured that every bracket produced would have the exact geometry validated by our FEA simulation.

Protective Electroplating for a Tough Finish

To protect the hot-rolled steel from corrosion in industrial environments, each bracket was finished with a durable, protective electroplating. This tough coating provided a long-lasting barrier against rust and abrasion.

Rigorous Load Testing for Performance Validation

The final step was physical validation. We subjected sample brackets to a rigorous load testing protocol in our facility. We applied forces that simulated and exceeded the specified working conditions to confirm that the parts performed exactly as predicted by our FEA analysis.

The Result: Ultra-Durable Industrial Hardware that Delivered

The outcome was a heavy-duty bracket that not only met but surpassed the client's performance targets. Our engineering-first approach delivered a solution they could trust.

A Bracket That Surpassed Durability Targets

The final product proved to be exceptionally resistant to both static and dynamic loads. The combination of an optimized design and robust material resulted in one of the most durable metal fittings in our client's portfolio.

Enabling a More Robust and Reliable Product for Our Client

By providing this ultra-reliable piece of industrial hardware, we enabled our client to build a more robust and dependable industrial cart, enhancing their brand's reputation for quality and durability.

More Than a Stamper: Your Engineering Partner for Heavy-Duty Applications

This case study demonstrates that Pengce Metal is more than just a stamping company; we are an engineering partner. We use modern tools like FEA and physical load testing to ensure the solutions we provide are not just made correctly, but designed correctly. What is the most common failure mode you see in industrial hardware? Is it bending, cracking, or corrosion? Share your insights!

Your Questions on Custom Heavy-Duty Brackets Answered

What is Finite Element Analysis (FEA) and why is it useful? What is FEA?It is a computerized method for predicting how a product reacts to real-world forces. By simulating stress, vibration, and other physical effects on a digital model, we can identify potential design flaws and optimize a part for maximum performance before building an expensive physical prototype.

Can you add features like ribs or gussets to a stamped bracket to increase strength?Yes. Adding reinforcing features like stamped ribs or gussets is a highly effective and cost-efficient way to increase a bracket's stiffness and strength without significantly increasing its weight or material cost. This is a common technique we use in design optimization.

What other materials are suitable for heavy-duty brackets? What other materials are suitable?Besides hot-rolled steel, other options include thicker gauges of cold-rolled steel or various grades of stainless steel for applications requiring corrosion resistance. The best choice depends on the specific balance of strength, weight, corrosion resistance, and cost required.

How do you test the load capacity of a custom bracket? How do you test load capacity?We use hydraulic presses or specialized test rigs to apply a controlled force to the bracket. We measure the force at which the part begins to permanently deform (yield strength) and the force at which it ultimately breaks (tensile strength) to validate its real-world performance. For an analysis of your custom part, contact the Pengce Metal engineering team.