The properties of a metal part are not set in stone. Through the science of metallurgy, we can fundamentally change a metal's character, making it harder, stronger, or softer. This is achieved through the heat treatment process—a critical manufacturing step for improving part performance. This guide will explain what heat treatment is, explore the key processes, and show how it can unlock the true potential of your stamped metal parts.

Why is Heat Treatment Necessary in Manufacturing?

Why is heat treatment necessary? It's a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing the product's shape. Its primary purposes are:

Enhancing Hardness and Wear Resistance

For components subjected to friction or abrasion, increasing surface hardness is crucial. Heat treatment can make a metal part significantly more resistant to wear, extending its service life.

Increasing Strength and Toughness

Heat treatment can dramatically increase a material's strength, allowing it to withstand higher loads. Importantly, it can also enhance toughness, which is the ability to absorb energy and resist fracturing.

Relieving Internal Stresses

Manufacturing processes like stamping and welding can introduce internal stresses into a part. Stress relieving is a form of heat treatment that reduces these stresses, minimizing the risk of distortion or cracking later in the product's life.

Improving Ductility and Machinability

Conversely, heat treatment can also be used to make a material softer and more ductile. This process, known as annealing, makes the metal easier to stamp, form, or machine.

Key Heat Treatment Processes Explained

There are several core types of heat treatment, each designed to achieve a specific outcome.

Hardening: The Quenching and Tempering Process

Metal hardening is used to increase a metal's strength and wear resistance. For steels, this is typically achieved through quenching and tempering, a two-step process that creates a hard, yet tough, final structure.

Annealing: Softening Metal for Easier Forming

Annealing is essentially the opposite of hardening. The metal is heated and then very slowly cooled. This process softens the metal, increases its ductility, and makes it much easier to work with in subsequent forming operations.

Normalizing: Refining the Grain Structure

Normalizing is a process that creates a more uniform and refined internal grain structure in steel. This improves both strength and toughness. It is often performed on components that will be subjected to high stress.

Stress Relieving: Reducing Risk of Distortion

This low-temperature process is used to reduce internal stresses that have built up during manufacturing. It is a vital step for complex parts or those with tight dimensional tolerances to ensure long-term stability.

A Deep Dive into Quenching and Tempering for Metal Hardening

The most common heat treatment for improving part performance in terms of strength is quenching and tempering. Let's break down how it works.

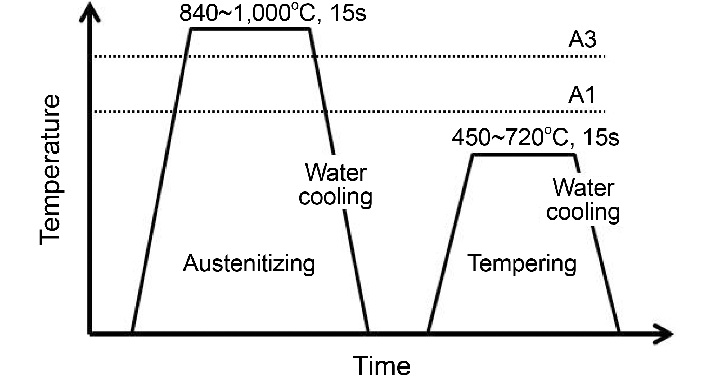

Step 1: Heating to Austenitizing Temperature

The steel part is heated in a controlled furnace to a specific, high temperature (the austenitizing temperature). At this temperature, the internal crystal structure of the steel changes into a phase called austenite.

Step 2: The Quench - Rapid Cooling in Oil, Water, or Air

Once the part is uniformly heated, it is rapidly cooled—or quenched—in a medium like oil, water, or even air. This rapid cooling traps the carbon atoms and transforms the austenite into martensite, a very hard but brittle structure.

Step 3: Tempering to Achieve Desired Toughness

The final, crucial step is tempering. The hardened, brittle part is reheated to a much lower temperature and held for a specific time. This process relieves some of the internal stress and reduces brittleness, imparting the necessary toughness to the final component.

When to Integrate Heat Treatment in the Stamping Workflow

The heat treatment process can be applied at different stages of manufacturing, depending on the goal.

Heat Treating Before Stamping (Annealing)

If a material is too hard to be stamped into a complex shape, it is first annealed. The annealing process makes the material soft and pliable, allowing it to be formed without cracking.

Heat Treating After Stamping (Hardening)

More commonly, a part is stamped from a softer material and then heat-treated afterwards to achieve the final desired properties. This metal hardening approach is used for components like springs, clips, and brackets that need high strength and wear resistance. For an expert review of your project's needs, contact the Pengce Metal team.

Unlocking Your Material's Full Potential with Expert Heat Treatment

The heat treatment process is a powerful tool in a manufacturer's arsenal. It allows us to take a standard material and tailor its properties to meet the most demanding performance requirements. Executing this process with precision requires deep metallurgical knowledge and highly controlled equipment. By partnering with an expert, you can ensure that you are truly unlocking your material's full potential. Which material property is most critical for your application: hardness, toughness, or ductility? Let us know in the comments!

Your Questions About the Heat Treatment Process Answered

What is the main difference between annealing vs hardening?What is the difference between annealing vs hardening? They are opposite processes. Annealing makes a metal softer and more ductile by heating it and cooling it very slowly. Hardening (quenching and tempering) makes a steel harder and stronger by heating it and cooling it very rapidly, followed by a second heating at a lower temperature.

Does heat treatment cause parts to distort or change size?Does heat treatment cause distortion? Yes, it can. The rapid heating and cooling cycles can cause parts to warp or change dimensions slightly. A skilled heat treater anticipates these changes and can use specialized fixtures and techniques to minimize distortion on parts with tight tolerances.

Can all metals be heat treated?No. The ability to be significantly hardened by heat treatment is primarily a property of steels with sufficient carbon content (typically >0.3%). While some aluminum and titanium alloys can be heat-treated, many metals like pure copper or certain stainless steels do not respond to hardening in the same way.

How do you verify that a part has been correctly heat treated?How do you verify heat treatment? The primary method is a hardness test. We use a Rockwell hardness tester to measure the part's surface hardness and verify that it falls within the specified range (e.g., 44-52 HRC). This test confirms that the heat treatment process was successful. For your quality-critical parts, reach out to our team today.