"How much will this cost?" It's often the first and most important question when developing a new product. There's a common myth that "custom" always means "expensive," but this isn't necessarily true. While there is an initial investment, metal stamping is inherently a method for cost-effective manufacturing, especially at scale. Understanding the factors that influence metal stamping cost is the first step to achieving affordable custom parts. This guide will break down the real costs and show you how to optimize your budget.

The Two Main Components of Metal Stamping Cost

To understand the full picture, it's essential to recognize that the stamping parts price is composed of two distinct parts.

Tooling Cost: The One-Time Investment

The tooling cost is the upfront, one-time expense to design and build the custom stamping die for your specific part. This is the most significant initial investment. A high-quality tool is crucial for producing accurate parts consistently over a long period.

Part Price: The Ongoing Per-Piece Cost

The part price is the cost you pay for each individual piece produced. This cost includes raw material, machine run-time, labor, and any secondary operations. As you'll see, this price is heavily influenced by the total production volume.

Key Factor 1: Part Complexity and Design

The single biggest driver of tooling cost is the complexity of your part's design. The more intricate the design, the more complex and expensive the tool will be to build.

How Tight Tolerances Increase Tooling Complexity

Parts with very tight tolerances require a more precise—and therefore more expensive—die. The tool needs to be built with extremely high accuracy and may require more stages to ensure every dimension is perfect, which increases the overall part complexity.

The Impact of Deep Draws and Complex Bends

Features like deep draws (forming cup-like shapes) or multiple complex bends require more sophisticated and robust tooling. These features increase the forces on the tool and the material, necessitating a more advanced and costly die design.

Pro Tip: Simplify Your Design for Major Savings

How to reduce stamping parts cost? The easiest way is through smart design for cost. Work with your manufacturer's engineers. Sometimes a small, non-critical design tweak can dramatically simplify design and tooling, leading to significant savings without compromising function.

Key Factor 2: Material Selection and Thickness

The material you choose has a direct impact on both the tooling and the per-part price. This is one of the key sheet metal cost factors.

The Price Difference Between Steel, Aluminum, and Copper

Your material selection is a major cost driver. Commodity materials like carbon steel are generally the most affordable. Aluminum is typically next, followed by more expensive materials like stainless steel, copper, and brass.

Why Thicker Material Means Higher Costs

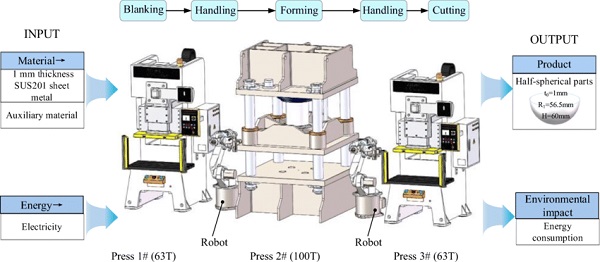

Thicker materials require more force to cut and form. This means a larger, more powerful press is needed, and the stamping die must be built to be much stronger and more durable. This increases both the tooling cost and the energy consumed per part.

Key Factor 3: Production Volume (The Power of Scale)

Metal stamping truly shines in medium to high-volume production. The power of scale is the key to unlocking its cost-effectiveness.

How Higher Volumes Drastically Reduce Per-Part Price

As production volume increases, the per-part price drops significantly. This is because setup times, labor, and machine operation become much more efficient when producing thousands or millions of parts continuously, compared to just a few hundred.

Amortizing Your Initial Tooling Investment

Higher volumes allow you to spread the initial tooling cost over a much larger number of parts. For example, a $10,000 tool cost is $1 per part for 10,000 pieces, but only $0.01 per part for 1,000,000 pieces. This process of amortizing the investment is what makes stamping so economical at scale. For your next high-volume project, consult with the experts at Pengce Metal.

Key Factor 4: Secondary Operations and Finishes

The final cost must include any steps that happen after the part comes off the press. These secondary operations add value but also contribute to the final price.

Factoring in Costs for Plating, Anodizing, or Assembly

If your part requires finishing touches like electroplating, anodizing, heat treatment, or assembly with other components, these processes will add to the total stamping parts price. It's important to account for these from the beginning.

Pro Tip: Can a Design Change Eliminate a Secondary Step?

Sometimes, a clever design change can eliminate the need for a secondary operation. For example, designing a snap-fit feature might remove the need for later assembly with screws. Always ask if functions can be integrated directly into the stamped part.

Partnering for Cost-Effective Manufacturing Solutions

Understanding metal stamping cost is about seeing the big picture. The cheapest quote isn't always the best value if the tooling wears out quickly or part quality is inconsistent. A true partner for cost-effective manufacturing will work with you to optimize your design and process for the lowest total cost over the product's lifetime. What's your biggest concern when it comes to budgeting for custom parts? Let's discuss cost-saving strategies in the comments!

Your Metal Stamping Cost Questions Answered

Is metal stamping cheaper than CNC machining?For high volumes, almost always yes. CNC machining has no tooling cost, making it ideal for prototypes and low volumes. However, its per-part price is much higher. Once production volume is high enough to amortize the tooling cost, metal stamping becomes significantly cheaper per part.

Why is the tooling cost so high for a simple part?Even a "simple" part requires a custom tool made from hardened steel, machined to high precision. The cost reflects the skilled labor, engineering design time, and high-quality materials needed to create a durable and accurate custom tool and die.

Can you give me a price for a part without a drawing?Unfortunately, no. How much does metal stamping cost? It's impossible to answer without a technical drawing. The cost is entirely dependent on the part's specific geometry, dimensions, tolerances, and material, which can only be understood from a detailed drawing.

How can I get an accurate quote for my stamping parts price?How to get an accurate quote? Provide a complete technical drawing (2D or 3D model), specify the material and thickness, state the required annual or batch quantity, and list any finishing or secondary operations. The more detailed your information, the more accurate our quote will be. Submit your design for a free quote today.